1 月 . 26, 2025 02:20

Back to list

89M Truss Ferris Wheel

Exploring the Future of Entertainment The Innovative World of 3D Printed Roller Coasters

Expertise in the field is essential to ensuring the success of these next-generation coasters, as the design and engineering processes can be complex. Companies specializing in 3D printed structures must possess a deep understanding of material science, structural engineering, and computational design. This level of expertise is pivotal in creating safe and reliable rides that meet rigorous industry standards. Comprehensive tests and thorough certifications are crucial to establish the trustworthiness of 3D printed roller coasters. By working closely with regulatory bodies and adhering to strict safety protocols, manufacturers can ensure that each ride is safe for public use. Trust is further built by the transparency of material sourcing and the implementation of advanced simulation software that predicts performance under various conditions. Additionally, the maintenance of 3D printed roller coasters benefits from the modular nature of their construction. Should a component need replacement or modification, parks can simply print out new parts, drastically reducing downtime and costs. This adaptability not only keeps the rides operating smoothly but also ensures they remain state-of-the-art attractions. The impact of 3D printed roller coasters extends beyond the amusement parks themselves. As more parks adopt this technology, there is a potential reduction in environmental impact due to the efficiency and precision of 3D printing, which minimizes material waste. This aligns with the growing consumer demand for sustainability in entertainment experiences. In conclusion, 3D printed roller coasters are at the forefront of amusement park innovation, offering unparalleled design freedom, safety, and sustainability. As the technology continues to evolve, its influence on the entertainment industry is likely to expand, promising more exciting developments on the horizon. Park operators and manufacturers who embrace this technology will not only set themselves apart as industry leaders but also captivate the imagination of thrill-seekers around the world.

Expertise in the field is essential to ensuring the success of these next-generation coasters, as the design and engineering processes can be complex. Companies specializing in 3D printed structures must possess a deep understanding of material science, structural engineering, and computational design. This level of expertise is pivotal in creating safe and reliable rides that meet rigorous industry standards. Comprehensive tests and thorough certifications are crucial to establish the trustworthiness of 3D printed roller coasters. By working closely with regulatory bodies and adhering to strict safety protocols, manufacturers can ensure that each ride is safe for public use. Trust is further built by the transparency of material sourcing and the implementation of advanced simulation software that predicts performance under various conditions. Additionally, the maintenance of 3D printed roller coasters benefits from the modular nature of their construction. Should a component need replacement or modification, parks can simply print out new parts, drastically reducing downtime and costs. This adaptability not only keeps the rides operating smoothly but also ensures they remain state-of-the-art attractions. The impact of 3D printed roller coasters extends beyond the amusement parks themselves. As more parks adopt this technology, there is a potential reduction in environmental impact due to the efficiency and precision of 3D printing, which minimizes material waste. This aligns with the growing consumer demand for sustainability in entertainment experiences. In conclusion, 3D printed roller coasters are at the forefront of amusement park innovation, offering unparalleled design freedom, safety, and sustainability. As the technology continues to evolve, its influence on the entertainment industry is likely to expand, promising more exciting developments on the horizon. Park operators and manufacturers who embrace this technology will not only set themselves apart as industry leaders but also captivate the imagination of thrill-seekers around the world.

Next:

Latest news

-

Top Amusement Equipment Manufacturer Rock n Roller Coaster & Carousel ManufacturerJun.10,2025

-

World's Scariest Roller Coaster Experience Ultimate Thrill & HeightJun.10,2025

-

Ultimate Thrill Ride Roller Coaster High-Speed, Safe AdventureMay.30,2025

-

Carousel Mansfield Rides Premium Indoor & Event SolutionsMay.30,2025

-

T3 Roller Coaster High-Thrill, Safe Ride for Theme Parks & ResortsMay.30,2025

-

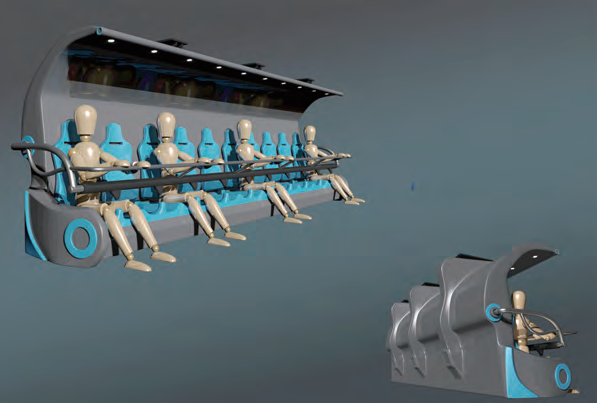

Roller Coaster Cart Design Custom-Built & High-Safety Thrill Ride VehiclesMay.30,2025