3 月 . 06, 2025 13:09

Back to list

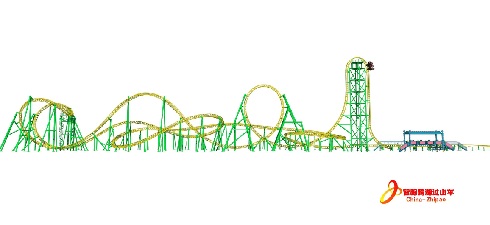

3d printed roller coaster

Exploring the world of 3D printed roller coasters offers an exhilarating glimpse into the future of amusement parks and personalized fun experiences. With the advent of 3D printing technology, designers and engineers are pushing the boundaries of what's possible, crafting roller coasters that were once only dreamt of in the imagination. This innovative method is not only transformative for roller coaster aficionados but also for the amusement park industry, marking a new era of customized and eco-friendly rides.

Trust in the durability and safety of 3D printed roller coasters is gaining ground, as technological advancements continue to make significant strides. Rigorous testing and simulations are conducted to ensure that these coasters can withstand extreme conditions and offer a safe experience for thrill-seekers. With technology ensuring precision and reliability, theme parks worldwide are beginning to embrace 3D printing not only for its efficiency but also for its ability to deliver unique and safe experiences. As more theme parks adopt 3D printing technologies, the cost efficiency becomes apparent. Traditional manufacturing techniques often require substantial investments in molds and tooling; in contrast, 3D printing requires fewer initial outlays and reduces material waste. This efficiency translates into cost savings that can be passed on to park-goers, making the thrilling experience of riding a custom-designed roller coaster accessible to a broader audience. The potential of 3D printed roller coasters extends beyond amusement parks. Educational institutions are beginning to incorporate this technology into curricula, offering students hands-on experience with design and engineering projects centered around roller coasters. This fosters a new generation of innovative thinkers who are not only skilled in modern technology but also passionate about pushing the boundaries of design and engineering. The future of roller coasters is indeed exciting. With 3D printing at the helm of innovation, the amusement industry stands on the cusp of a revolution, offering limitless possibilities for creativity, sustainability, and personalized experiences. The integration of 3D printing not only redefines the dynamics of roller coaster design but also builds a foundation of trust and authority that positions this technology as a pillar of modern amusement parks. Whether for thrill or education, 3D printed roller coasters symbolize a harmonious blend of technology and imagination, paving the path toward a new legacy in entertainment.

Trust in the durability and safety of 3D printed roller coasters is gaining ground, as technological advancements continue to make significant strides. Rigorous testing and simulations are conducted to ensure that these coasters can withstand extreme conditions and offer a safe experience for thrill-seekers. With technology ensuring precision and reliability, theme parks worldwide are beginning to embrace 3D printing not only for its efficiency but also for its ability to deliver unique and safe experiences. As more theme parks adopt 3D printing technologies, the cost efficiency becomes apparent. Traditional manufacturing techniques often require substantial investments in molds and tooling; in contrast, 3D printing requires fewer initial outlays and reduces material waste. This efficiency translates into cost savings that can be passed on to park-goers, making the thrilling experience of riding a custom-designed roller coaster accessible to a broader audience. The potential of 3D printed roller coasters extends beyond amusement parks. Educational institutions are beginning to incorporate this technology into curricula, offering students hands-on experience with design and engineering projects centered around roller coasters. This fosters a new generation of innovative thinkers who are not only skilled in modern technology but also passionate about pushing the boundaries of design and engineering. The future of roller coasters is indeed exciting. With 3D printing at the helm of innovation, the amusement industry stands on the cusp of a revolution, offering limitless possibilities for creativity, sustainability, and personalized experiences. The integration of 3D printing not only redefines the dynamics of roller coaster design but also builds a foundation of trust and authority that positions this technology as a pillar of modern amusement parks. Whether for thrill or education, 3D printed roller coasters symbolize a harmonious blend of technology and imagination, paving the path toward a new legacy in entertainment.

Next:

Latest news

-

Top Amusement Equipment Manufacturer Rock n Roller Coaster & Carousel ManufacturerJun.10,2025

-

World's Scariest Roller Coaster Experience Ultimate Thrill & HeightJun.10,2025

-

Ultimate Thrill Ride Roller Coaster High-Speed, Safe AdventureMay.30,2025

-

Carousel Mansfield Rides Premium Indoor & Event SolutionsMay.30,2025

-

T3 Roller Coaster High-Thrill, Safe Ride for Theme Parks & ResortsMay.30,2025

-

Roller Coaster Cart Design Custom-Built & High-Safety Thrill Ride VehiclesMay.30,2025