Innovative Designs in 3D Printed Roller Coasters for Thrilling Amusement Park Experiences

The Marvel of 3D Printed Roller Coasters

In recent years, the advent of 3D printing technology has not only transformed industries such as manufacturing, healthcare, and architecture, but it has also begun to make its mark in the realm of amusement parks and entertainment. Among the most exhilarating applications of this technology is the creation of 3D printed roller coasters. These innovative attractions are revolutionizing the way theme park rides are designed, constructed, and experienced.

Traditionally, building a roller coaster involves a lengthy and expensive process that includes extensive planning, engineering, and construction. However, with the emergence of 3D printing, the development timeline has drastically reduced. Designers can create intricate models and prototypes in a fraction of the time it would have taken using traditional methods. This acceleration allows for more dynamic designs that push the boundaries of what is possible in terms of coaster shapes and features.

The Marvel of 3D Printed Roller Coasters

Moreover, 3D printing designs can incorporate advanced technologies such as sensors and smart systems that enhance rider safety and experience. For example, automated systems can monitor the structural integrity of the coaster in real-time, alerting park operators to potential issues before they become safety hazards. Additionally, features such as integrated lighting effects and sound systems can be seamlessly embedded within the coasters, elevating the thrill and immersiveness of the ride.

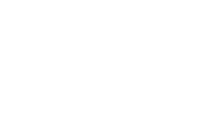

3d printed roller coaster

Another significant benefit of 3D printed roller coasters is the potential for customization. Parks can create themed attractions that resonate with specific audiences or events. Imagine a roller coaster designed specifically for a movie franchise, complete with elements that mimic scenes from the films. Or consider a coaster that changes with the seasons, featuring different colors and effects throughout the year. This level of personalization can attract a diverse range of visitors, catering to families, thrill-seekers, and fans of specific franchises alike.

Additionally, the environmental impact of 3D printing in roller coaster construction is an important factor to consider. Traditional building methods often result in substantial waste, as materials are cut and carved from larger blocks. In contrast, 3D printing uses only the necessary amount of material, significantly reducing waste. As the global focus on sustainability intensifies, this eco-friendly approach is likely to appeal to both park operators and environmentally conscious visitors.

Despite the excitement surrounding 3D printed roller coasters, challenges remain. The technology is still evolving, and ensuring structural integrity under the stresses of high-speed rides is paramount. Future advancements in material science and engineering will play a crucial role in addressing these concerns, paving the way for even more ambitious designs.

In conclusion, the fusion of 3D printing technology and roller coasters represents a thrilling frontier in the amusement park industry. With its potential to reduce costs, enhance creativity, and promote sustainability, the rise of 3D printed roller coasters can truly revamp the experience of thrill-seekers around the globe. As parks continue to embrace this innovative technology, we can expect to see more imaginative and exhilarating rides that capture the spirit of adventure and creativity that characterize theme parks. The future of roller coasters is not just being built—it's being printed.

-

Top Amusement Equipment Manufacturer Rock n Roller Coaster & Carousel ManufacturerJun.10,2025

-

World's Scariest Roller Coaster Experience Ultimate Thrill & HeightJun.10,2025

-

Ultimate Thrill Ride Roller Coaster High-Speed, Safe AdventureMay.30,2025

-

Carousel Mansfield Rides Premium Indoor & Event SolutionsMay.30,2025

-

T3 Roller Coaster High-Thrill, Safe Ride for Theme Parks & ResortsMay.30,2025

-

Roller Coaster Cart Design Custom-Built & High-Safety Thrill Ride VehiclesMay.30,2025